PRODUCTS

Coloring

for PLASTIC / GLASS

Colorants are mixed into plastic materials for containers and accessories to create original expressions ranging from transparent to opaque.

Coloring

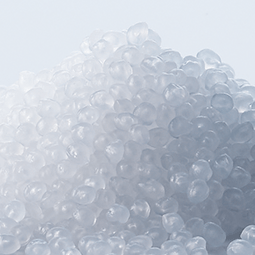

Base plastic pellets come uncolored.

Their color is called natural color (N) or original.

The tone of the origina color differs with materials: PP and

PE are milk white while PET

and PMMA are transparent.

Colors of typical base plastic pellets and example molded products

- PP

- PE

- PET

- PCT

- PMMA

- AS(SAN)

- ABS

※ When choosing a milk white material, please remember that it is not possible to make it transparent.

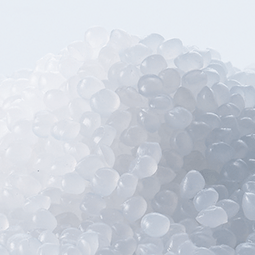

Example colors

Glass coloring

Glass bottles are originally colorless and transparent. They are colored by adding a small amount of colorant (metallic oxide). Their colors are limited and subject to inconsistency depending on the glass melting conditions. For automated bottle making*1, coloring is not1 a commonly used decoration technique due to the large lot size. However, for semi-manual bottle making*2, coloring is an option even for small lots.

- *1 Volume production of bottles typically for cosmetics and seasonings

- *2 Small-volume production of bottles such as for perfumes and fragrance oils

A variety of pigments

A wide array of expressions, such as pearly luster and shifts in color

depending on the viewing angle, helps create a luxurious appearance.

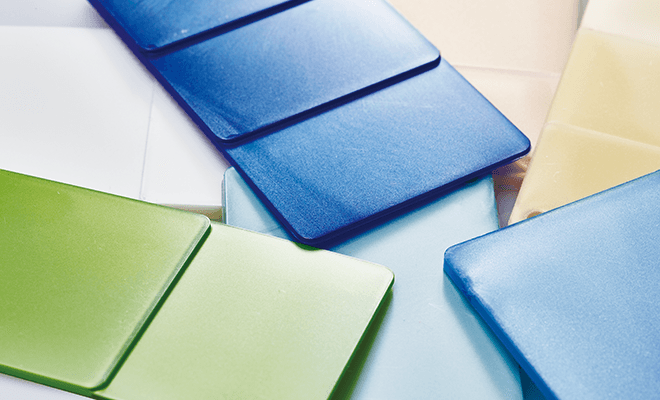

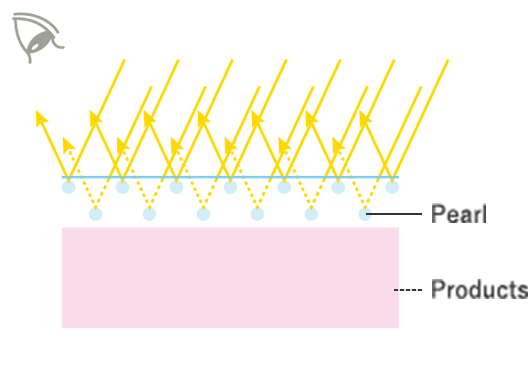

Pearl

The Pearl pigment is used to simulate a pearl-like luster. The color comes from multiple reflections produced by variations in refractive index resulting from different thicknesses of titanium oxide or other substances coated on mica or other substrates. Color variations of Pearl itself are also available.

For enhanced pearly luster

Use base plastic pellets that are transparent, translucent o light-colored.

Inhibited pearly luster

Opaque base plastic pellets result in poor pearly luster effects because the resultant product reflects light only at its surface.

Dark-colored base plastic pellets cancel the effects of Pearl and fail to produce the expected pearly luster.

※ If mica is used as a substrate, the level of coloring by the Pearl pigment is further reduced because the mica is crushed by heat or loading in the coloring stage.

Comparison of coloring and paint

Pearl coloring

Pearl paint

Where coloring does not seem to effectively produce a pearly luster, paint is recommended to achieve a pearly effect. Paint is useful for rendering beautiful pearly colors with a three-dimensional effect, since the process can be divided into base color and pearly color paint processes if needed.

Other pigments

METASHINE® glossy pigment

METASHINE® is a glossy inorganic pigment by which metal or metal oxide coatings on the substrate surfaces of glass flakes present a stylish gloss.

The photo shows METASHINE® (silver) added to brown.

LG neo® glossy pigment

LG neo® is metal powder produced using a vacuum metalized process, instead of using aluminum flakes.A plastic-sandwiched metal layer resists acidic, alkaline or solvents to retain glossiness. Blending with a colorant is not the sole option; coloring the plastic layer of the pigment makes a glossy colored metal powder possible.The photo shows LG neo® (silver) added to pink.

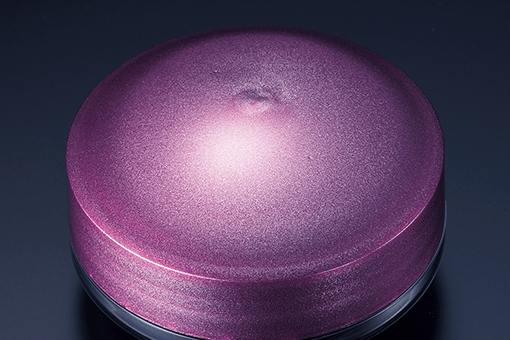

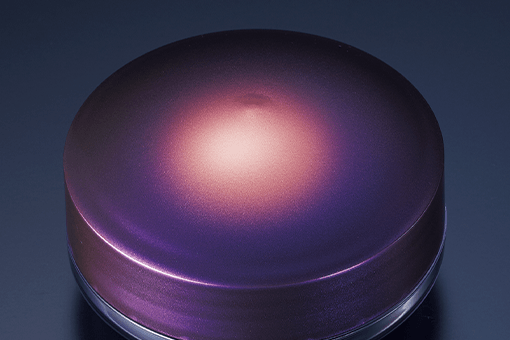

CHROMASHINE® polarizing pigment

Inorganic or organic multilayer films are formed on aluminum flakes to render a variety of colors and shifts in color (polarization). CHROMASHINE® gives the product a metallic appearance and, unlike conventional polarizing pigments, has high hiding power. Choose from the prearranged color variations to provide a metallic finish. Addition of another colorant will impair the pigmentʼs properties. The photo shows violet CHROMASHINE®.

Additives that add functionality

Photochromic

Purple color: Before UV irradiation

Purple color: After UV irradiation

Since the color appears when exposed to ultraviolet rays, it can be used on containers of sunscreen and other products as a guide for application. Photochromic is available in six colors: yellow, pink, purple, violet, blue, and green.

- UV absorbent

- This is added to prevent deterioration of the contents due to ultraviolet rays.

- Antibacterial

- This additive is used to inhibit bacteria such as E. coli and Staphylococcus aureus. Unlike disinfectants that kill bacteria, this product uses safe silver ions to inhibit bacterial growth.

- Light diffusing agent

- It can be added to highly transparent resins to create a frosted glass-like effect, and can be used in LED lighting covers to enhance the luxurious feel of the product.

- Thermochromic

- This is a colorant (master batch) that changes with temperature. Various combinations are possible, such as colorless to colored, or colored to colorless.

Case Study

- 1. CORONA-80(coloring, silk screen printing)+ CLO-80C(coloring, silk screen printing )

- 2. IBT-100A(coloring, silk screen printing )+ Z-500-C001(coloring)

- 3. OBR-350(coloring, silk screen printing, adhesive label )+ Z-3000-C062(coloring)

- 1. TORTE-50(Inner Jar: coloring / Outer jar : coloring (METASHINE®), silk screen printing)+ BTA-CAP(Cap: coloring / Top panel : coloring)

- 2. ATTO-50 (Inner Jar : coloring (peal), silk screen printing)+ ATTO-50CAP(coloring (peal), hot stamping)

- 3. MINI DORA (Body : natral color / Cap : colorinng (CHROMASHINE®), silk screen printing, pad printing)

- 4. MINI DORA(Body : natural color / Cap : coloring (LG neo®), silk screen printing, pad printing)