Container Rinsing

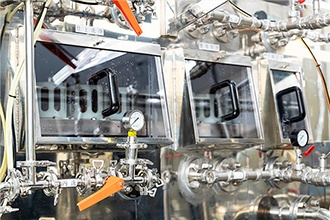

Rinsing of Glass Containers

Customers demand the cleanest possible glass containers, so we have set up a rinsing line for glass containers. The line is used for extensive applications, including pharmaceutical and electronics materials, as well as containers for reagents and industrial chemicals.

We offer options for your specific purposes, ranging from simple rinsing for removing foreign matter to high-purity rinsing for removing fine particles. The rinsing capability extends from small containers such as vials and standard bottles to gallon bottles and other large containers, as well as wide-mouthed and narrow-mouthed glass bottles.

Click here for containers that can be rinsed.

※ GLASEL handles high-purity rinsed containers compliant with semiconductor grade (Electronic Grade) (rinsing with ultrapure water).

Rinsing flow

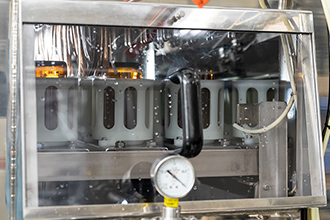

Preliminary rinsing

The purpose is to remove large foreign matter. Preliminary rinsing uses the water from circulation rinsing.

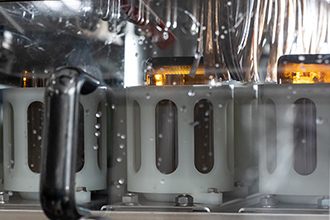

Circulation rinsing

Intended to remove smaller foreign matter. Circulation rinsing uses the water from finish rinsing. The water in turn is used in preliminary rinsing.

Finish rinsing (rinsing with pure water)

The container interior is rinsed with pure water. Stepwise rinsing minimizes contamination of the pure water and is efficient.

Drying (Blowing by air + Drying with heat)

The drying process is also performed in the rinsing machine. Moisture is removed through blowing by air and the container is dried with heat.

Packing

Different tape colors are used to visually distinguish between rinsed and unrinsed containers.

Shipping

Reliable shipping is ensured by checking the actual articles against invoices at the logistics warehouse.

※ The above process steps are given for example purposes only.

Options

Measurement

Measurement services are available according to your needs such as in-liquid particle counting and chemical component inspections. Please ask us about measurement reports, inspection sheets, and measurements in accordance with your standards.

Packing

We can satisfy various packing requirements such as shrink packaging, large bags, and parchment paper, according to your specific application.

Dealkalization

Dealkalization can be performed to reduce the leaching of alkaline components. Bottles can also be shipped after dealkalization followed by rinsing. (Left: dealkalized bottle; right: dealkalized and rinsed bottle)

About dealkalization

This treatment reduces the leaching of alkaline components from glass bottles (also known as sulfur treatment). Ammonium sulfate is placed in the bottle, which reacts with sodium ions in the glass and thus reduces the leaching of alkaline components. Dealkalization produces sodium sulfate, which turns the bottle surface cloudy white; it can be rinsed away.

Sterilization

When you need containers for products for areas around the eyes, for paraben-free cosmetics, or require medium sterilization, consult us. We will suggest a suitable sterilization method.

Examples: ethylene oxide gas (EOG) sterilization, electron beam (EB) sterilization, gamma irradiation sterilization, and vaporized hydrogen peroxide (VHP) sterilization

If you require cleaning or processing of containers other than the above, consult us.

Contact us here.