We want to select from general-purpose molds

and make the container original by coloring, printing

and other decorative techniques.

To choose a product, please use our catalog or visit our showroom. We will listen to your request (product image, budget, quantity, etc.), suggest the ideal container and help you make a decision.

We will send (or you can take) sample containers to your office for closer examination.

About Support

02

Examining

specifications

and design

We will suggest decoration methods (coloring/printing) tailored to your request. Our showroom exhibits various decoration examples.

Gallery

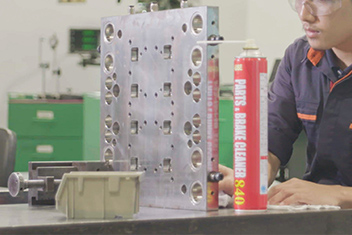

Before full-scale (volume) production, you and GLASEL check the quality of prototypes. We can also provide printing and other secondary processing services for molded products.

We will ship products that have passed quality checks.

About Quality Control

The above process steps are given for example purposes only.

The process sequence is subject to change or partial omission

with your consent according to your preferred delivery schedule or other conditions.

All original

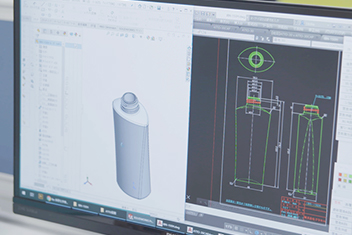

We work with our design division and manufacturers to design the final shape from a technical perspective, taking into account the formability and other factors based on the sketches and drawings for a planned product. We can also suggest shape designs in cooperation with our contract designers upon request.

About Product Development

02

Check the shape

with the model

We can create 3D models at the Mock Labo model workshop to enable customers to check the shape.

About Mock Lab

03

Examining

specifications

and design

We will propose a decorating method (color and printing) that meets your needs.

Click here for image gallery

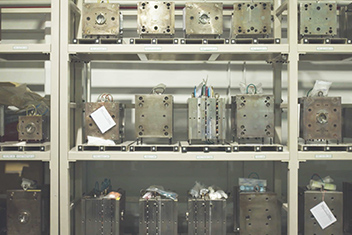

Fabrication of mold starts.

Before full-scale (volume) production, you and GLASEL check the quality of prototypes. We can also provide printing and other secondary processing services for molded products.

We will ship products that have passed quality checks.

About Quality Control

The above process steps are given for example purposes only.

The process sequence is subject to change or partial omission

with your consent according to your preferred delivery schedule or other conditions.