PRODUCTS

Vacuum

Metalized

for PLASTIC / GLASS

Vacuum metalized is a process of evaporating metal (usually aluminum [Al]) to form a metal coating on the surface of a substrate. Select this method when you need an aesthetically pleasing metallic color.

Vacuum MetalizedVacuum Metalized (dry plating)

Aluminum is most commonly used in containers

which are vacuum metalized.

This type of vacuum metalized material is heated in a

vacuum chamber and vaporized.

The vapor adheres to the

surface of a substrate and forms a thin film.

The chamber is vacuumed in order to prevent molecules

of the vaporized material

from colliding with molecules of

the gas in the chamber before reaching the substrate

and

to facilitate vapor deposition by lowering the evaporation

temperature of the

vaporized material.

Vacuum metalizing results in cleanly coated curved

surfaces even if hot stamping is

impractical. It is also

possible to add a desired color to the top coat over a

vacuum

metalized surface.

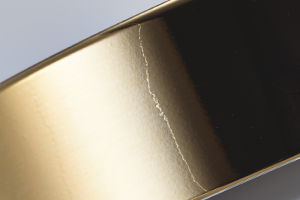

Left:Vacuum metalized(gloss)

Right:Vacuum metalized(matte)

Color variations

Vacuum Metalized Variations

Semitransparent Vacuum Metalized

The thickness of the metal film deposited in vacuum is controlled to obtain a metalized surface that transmits light. A container with this vacuum metalized film on the surface adds a metallic tint and enables the user to check the remaining amount of contents or to transmit light from within.

Differences between

Metal Covering,

Vacuum Metalized

and Hot Stamping

Metallic surfaces are formed by metal covering, vacuum metalized and hot stamping.

Metal Covering

A stamped metal part (aluminum) is fitted over a molded item.A back taper or other forms that are impossible to fit cannot be achieved by metal covering.

Metal covering reveals a boundary between the molded item and the metal part. The metal part feels cool to the touch.

※ For details, see “Metal Covering”

Vacuum Metalized

A molded item is vacuum metalized with aluminum.Three-dimensional curved surfaces can be vacuum metalized.

Hot Stamping

A foil is affixed to a molded item by pressure and heat.Hot stamping is suitable for two-dimensional curved surfaces, but not for three-dimensional curved surfaces.

A seam appears when hot stamping is applied on a side or other surfaces around which the foil is wrapped.

※ For details, see “Printing/Hot Stamping”

Various Pigments and Other Specs

Incorporating newer technologies,

these vacuum metalized options create distinctive appearance

which improve the image of your products.

Vacuum Metalized Variations

UV Large Grain Size METASHINE®

Color variations available

Vacuum Metalized (glossy pigment)

For this appearance, a topcoat paint colored with a pigment is applied onto the vacuum metalized surface. Large grain size METASHINE® is a glossy inorganic pigment such that metal or metal oxide coatings on the substrate surfaces of glass flakes present a stylish gloss. The larger grain size than that of the predecessor METASHINE® combined with a vacuum metalized finish make this outstanding.

※ Paints are also available to achieve this decoration (although the overall metallic appearance specific to vacuum metalized surfaces will be lost).

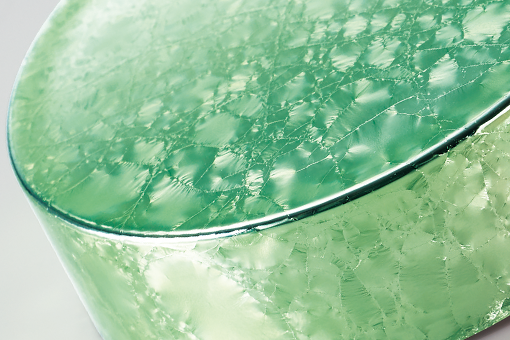

Crackle Vacuum Metalized

Color variations available

A special undercoat paint is applied to intentionally generate cracks in the vacuum metalized surface. Cracks enhance the effect of the reflective surface like a shiny water surface.

※ This technique produces nonuniform cracks.

Citrus Peel Vacuum Metalized

Color variations available

An undercoat paint with an additive is applied before being vacuum metalized to produce a texture that feels like a piece of citrus fruit peel. The surface feels rough and serves to make the product non-slippery. Several roughness options are available. (If a very rough additive is selected, the spray gun might become clogged. Choose from a permissible range of roughness.)

※ Paints are also available to achieve this decoration (although the overall metallic appearance specific to vacuum metalized surfaces will be lost).

Luminist® Vacuum Metalized (polarizing pigment)

For this appearance, a topcoat paint colored with a pigment is applied onto the vacuum metalized surface. Luminist® is a highly clear white pigment. When Luminist® is combined with a vacuum metalized surface, light is reflected and passes through the Luminist® layer again. The color is a bluish white pastel color when viewed from the direction of incidence. When viewed from the direction of reflection, the whitish Luminist® color diminishes into a strongly yellowish metallic color.

※ Color variations are available by adding a colorant to the topcoat. The result is a pastel color due to the characteristics of this polarizing pigment.

※ Luminist® vacuum metalized shows its characteristic effects when applied onto a vacuum metalized (silver) surface.

Antibacterial coating

This additive is used to inhibit bacteria such as E. coli and Staphylococcus aureus. Unlike disinfectants that kill bacteria, this product uses safe silver ions to inhibit bacterial growth.

Antiviral coating

The metal ions contained in the additive inhibit the multiplication of the virus by damaging its protein membrane.

Case Study

- 1. NP-30A(paint , silk screen printing )+Z-200SP(Closure:coloring /Rubber:flexible vacuum metalized)

- 2. IBJ-100L(coloring , silk screen printing , hot stamping)+CL-L(Inner cap:vacuum metalized/Outer cap:natural color)

- 3 .IBR-150A(gradient vacuum metalized , silk screen printing )+Z-500-C001(coloring )

- 1. ATTO-100(citrus peel vacuum metalized, silk screen printing )+ATTO-100CAP(citrus peel vacuum metalized)

- 2. CLEA-50(Inner jar:coloring/Outer jar:natural color, silk screen printing, hot stamping + CL-C(Outer cap:crackle vacuum metalized)

- 3. IBO-100L(UV large grain size METASHINE® vacuum metalized, silk screen printing , hot stamping )+SC-L(vacuum metalized)

- 4. IBR-150A(Luminist® vacuum metalized, silk screen printing )+IBR-150CAP(coloring )