PRODUCTS

Printing

for PLASTIC / GLASS

Freely select from a range of techniques for printing type and design to suit your specific material, item and design needs.

Silk screen printing

Silk screen printing, also known as screen printing,

can be used to print on almost any substrate

material

(except, it is said, air and water).

The technique can use a variety of inks.

Silk screen printing requires a screen, which used to be

made mainly of silk (hence the name of

the printing

method). Today, the screen is made of nylon or Teflon

(plain weave fabric).

A film positive of the original design is developed on the

screen to prepare a printing frame

(screen) whose mesh

is blocked except for the intended image.

An ink is poured into the printing frame, and a rubber

squeegee is moved over the screen.

The ink is thus transferred through the mesh and printed

onto a workpiece container.

Screen

Ink

Silver / Gold Colors

Gold pigmented

Silver pigmented

To print an image in silver or gold color, a special-purpose ink or medium into which a silver or gold pigment is mixed is used. These are known as “dull silver” or “dull gold.” However, since the result is a relatively dull color, hot stamping is recommended when a metallic appearance is desired.

※ The medium is a colorless clear ink, which is often used to thin pigments.

※ In some cases, to prepare a gold color, a silver pigmented ink or medium is used and color matched.

※ For details, see “Printing/Hot Stamping”

Screen Printing Variations

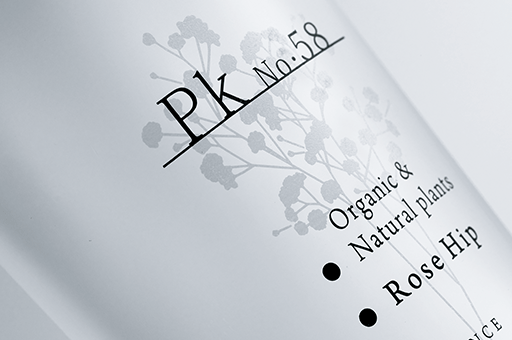

Organic Printing

This option features the use of organic ink. After printing, the ink is hardened in a drying oven. Organic printing enables colorful images to be flexibly printed on glass bottles, plastic jars and other containers. Organic printing can also be used for painted glass bottles or hot processed* workpieces. ( Approximate temperature of drying oven : 150‒180ºC for glass bottles, 50‒70ºC for plastic containers)

* For details, see “Printing/Hot Process”

UV Printing

This printing option uses UV ink made of a UV-sensitive plastic. Drying and hardening the ink quickly with ultraviolet rays, with little application of heat, UV printing is an option for plastics that are easily affected by heat. UV printing is often employed with automated machines that print two to four colors in a single process. It is more difficult to achieve color matching with this printing technique than organic printing.

Inorganic (Ceramic) Printing

Workpieces printed with ceramic ink comprising powder glass and inorganic pigments are baked in a furnace at a high temperature (approximately 600ºC). The ink fuses onto the glass surface. The result is a print that features strong adhesion and high durability, resisting peeling semi-permanently. Color matching, however, is difficult to achieve due to changes in color caused by baking.

※ Inorganic printing is suitable exclusively for glass bottles due to the need for baking at a high temperature. (It is not suitable for painted bottles because baking causes the paint to melt.)

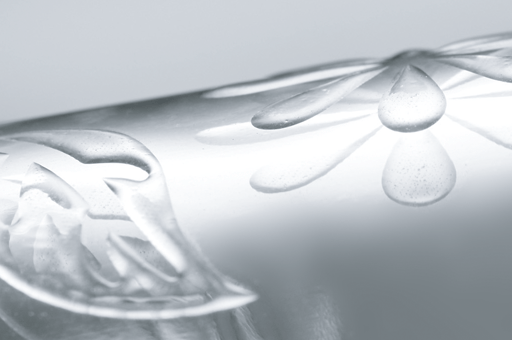

UV Thick Build-Up Printing

A short drying time required for UV printing makes it suitable for achieving a shiny, projecting expression by a thick build-up of ink.

※ This option is not suitable for small type or detail-oriented design.

※ The thick build-up is rounded.

Dry Offset Printing

The dry offset printing method is typically used to

print an image onto tubes.

The technique transfers or offsets (hence the name) inks

first from a plate cylinder

onto a blanket cylinder and then

to the workpiece,

instead of transferring inks directly from

the plate cylinder onto the workpiece.

While common offset printing involves the use of a

smooth-surface plate and water,

the dry offset printing

method uses relief printing plates and does not use water.

Ink is transferred from each color inking unit to relief

printing plates

and then sequentially to a blanket cylinder

(or a roller with a rubber sheet wound around).

A multi-colored image is printed from the blanket cylinder

to a tube in a single transfer cycle.

Both dry offset and screen printing techniques are widely

used for printing on tubes.

However, to print detailed designs or small characters, dry

offset printing is more suitable.

※ For common offset printing, see “Offset Printing”

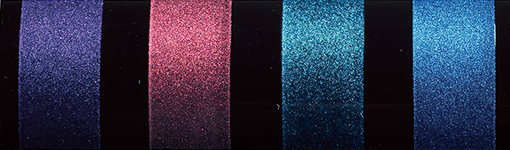

Gloss (Pearl) Pigment Printing

Xirallic®

Black substrate

White substrate

Frosted

Xirallic® is a glossy pigment made of artificially synthesized alumina flakes coated with a metal oxide. Compared with natural mica, alumina flakes have smoother surfaces and therefore have a higher gloss. In addition, Xirallic® is free of trace impurities that make the pigment yellowish. Since Xirallic® is mixed in medium ink for use for printing, its pearly effect is more outstanding when it is printed over a dark colored substrate.

※ Xirallic® is not suitable for type or detail-oriented design.

※The medium is a colorless clear ink, which is often used to thin pigments.

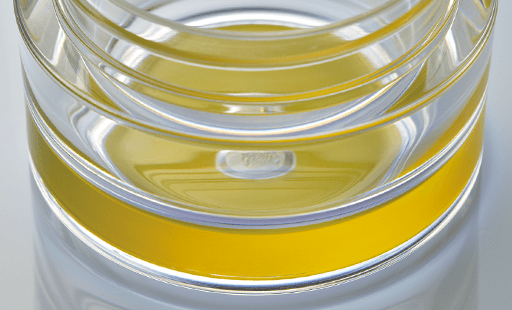

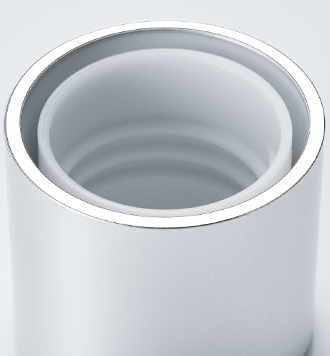

Printing on Bottom

Printing an image on the bottom of a thick molded container produces an impressive effect when viewed from the side. ( The same effect can also be achieved by paint.)

Hot Stamping /

Hot Process / Transfer

These decoration techniques involve placing and bonding

a hot stamping or

multicolor printing foil onto the

workpiece under heat and pressure.

The processes are classified as up-and-down

and roll-to-roll systems.

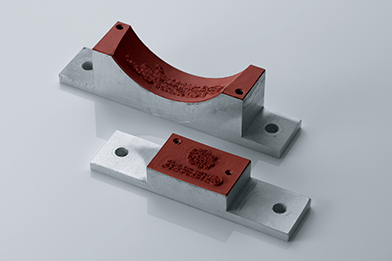

The embossed plate is called a

stamp, which is a part with

a carved design made of

rubber or the like.

Curved or flat plates are used

according to the workpiece shape.

※ These techniques are suitable for two-dimensional curved surfaces, but not for three-dimensional

curved surfaces, on which the foil would crease.

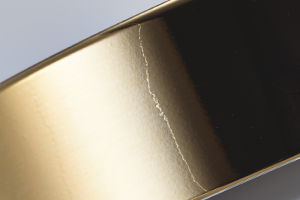

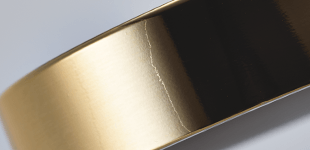

※Foil transferring all around a workpiece results in a seam at the overlap.

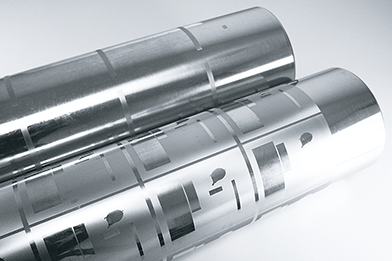

Hot Stamping

Stamps (top: curved plate bottom: flat plate)

Hot Process

Half-dry ink applied by silk screen printing is used as an adhesive to place a foil and bond onto the workpiece.

Hot Stamping Techniques

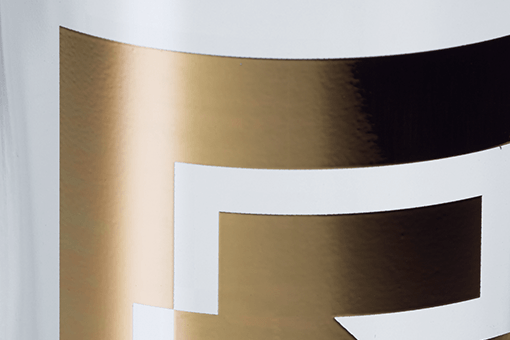

Hot Stamping (Roller)

A hot stamping foil is transferred to the side of a cap or dispenser. Some roller width options are available.

Hot Stamping (Cutout)

Hot stamping can use a foil with type or design cutouts.

※ Thin lines may not always be cut out.

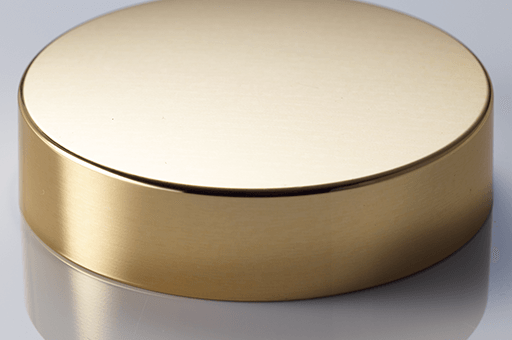

Hot Stamping

(Entire Surface)

Foils can be transferred to the entire top and side surfaces of a cap if it has no three-dimensional curved surface.

※ Foil transferring all around a workpiece results in a seam at the overlap.

Example Foils

Hot Stamping Foils

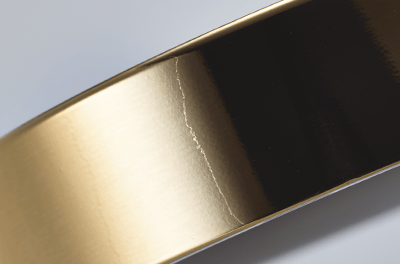

A hot stamping foil is a thermal transfer foil that comprises a main vacuum-metalized layer of aluminum or the like plu coloring, protective and adhesive layers. Hot stamping is the most effective of existing printing methods in achieving a metallic sheen (appearance). The luxury and strength of its plating-like mirror finish cannot be achieved by other printing techniques.

Metallic Foil

Metallic foil is the most standard vacuum metalized foil. I n addition to metallic aluminum foils, insulation foils and chromium foils are available.

Holographic Foil

In contrast to usual metallic foils that shine in a single color, holographic foils are special in that they shine with rainbow colors. Holographic foils with a specific, designed pattern are also available.

Polarizing Foil

Various shifts in color occur depending on the type of light source, such as natural light and indoor indirect illumination, and on the angle of reflection.

One-Way Mirror Foil

Unlike ordinary metallic foils, the thickness of the metal layer of a one-way mirror foil is controlled to be permeable to light entering from the back. Its light transmittance can be controlled, for example, between 10% and 41% to make the one-way mirror foil suitable for specific needs.

Transfer Foils

These transfer foils are thermal transfer foils with the design

(in monochrome, multicolor, vacuum metalized sheen, matte, etc.) printed on the film.

Matte Transfer Foil

Choose a matte transfer foil to fulfill your needs for a frosted*1 surface expression. The matte layer*2 is laid before design. After transferring the image, the matte layer stays on the film, leaving its effect on the workpiece as a (microscopically roughened) matte surface of the design. It is possible to make the surface either entirely or partially matte. The photo shows a partial matte surface.

*1. For details, see “Frost”

*2. The level of matte appearance is adjustable.

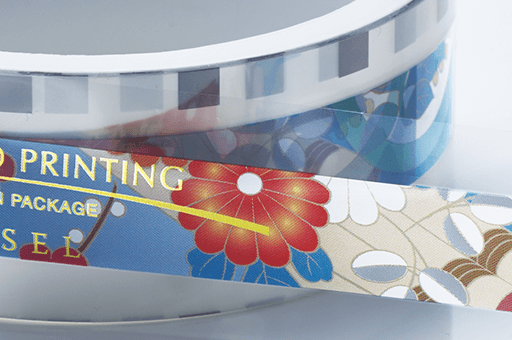

Multicolor Image Transfer Foil

This transfer technique transfers a multicolor image printed on a base film cleanly onto a container in a single process cycle. For this type of foil, gravure printing is typically used to print a full-color photo or to custom-color print a designated brand color. Moreover, a partial metalized foil option can be used to place a metallic logo or image in a design, thereby reducing the two conventional processes of silk screen printing and hot stamping to a single process.

※ For details, see “Gravure Printing”

Differences between

Metal Covering,

Vacuum Metalized

and Hot Stamping

Metallic surfaces are formed by metal covering, vacuum metalized and hot stamping.

Metal Covering

A stamped metal part (aluminum) is fitted over a molded item.A back taper or other forms that are impossible to fit cannot be achieved by metal covering.

Metal covering reveals a boundary between the molded item and the metal part. The metal part feels cool to the touch.

※ For details, see “Metal Covering”

Vacuum Metalized

A molded item is vacuum metalized with aluminum.Three-dimensional curved surfaces can be vacuum metalized.

※ For details, see “Vacuum Metalized”

Hot Stamping

A foil is affixed to a molded item by pressure and heat.Hot stamping is suitable for two-dimensional curved surfaces, but not for three-dimensional curved surfaces.

A seam appears when hot stamping is applied on a side or other surfaces around which the foil is wrapped.

Gravure / Flexo Printing / Offset

Gravure Printing

Plate

Gravure printing is used with films such as shrink films* , lamination pouches and transfer foil. Partially metalized gravure prints are also available.

* For details, see “Shrink Film”

Flexo printing

Due to its high printing rate and accuracy, this printing method is widely used for printing color photographic labels and shrink films.

※ For details, see “Shrink Film”

※ Flexo printing is not suitable for transfer foils.

Offset Printing

Due to its high printing rate and accuracy, this printing method is widely used for printing color photographic labels and shrink films.

※ For details, see “Shrink Film”

※ Offset printing can produce elaborate expressions such as photographs and gradient colors.

※ Printing techniques used for labels and shrink films include silk screen, on-demand and rotary letterpress printing. Rotary letterpress printing is suitable for sharply defined images. However, since it applies pressure directly during printing, the technique is not suitable for small type or thin lines.

※ The offset printing technique used for tubes is “dry offset printing”.

Pad / Fine / Ink-Jet

Pad Printing

Silicone pad / Plate

Pad printing is a type of offset printing, transferring ink from an intaglio plate first to a silicone pad and then to a workpiece. This printing method uses a soft pad, which is suitable for curved, convex and concave surfaces as well as flat surfaces. Pad printing uses fast-drying ink, enabling successive wet-on-wet printing (multicolor printing/overprinting). Since, however, the hiding power of a pad print is low, printed colors are affected by dark colored substrates.

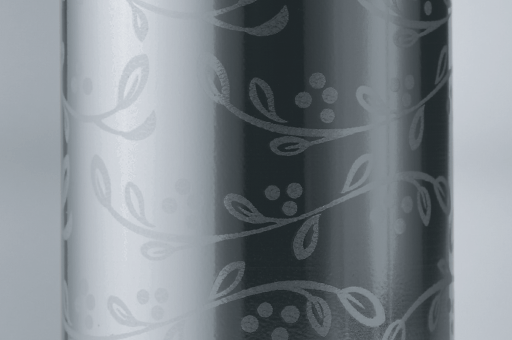

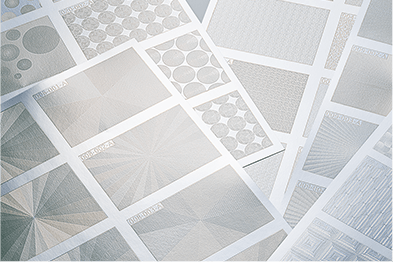

Fine Printing

Various patterns

Add a touch of originality to your image by incorporating a pattern into it. Use your original pattern or select from our rich collection of patterns. Colored images can also be fine printed. Fine printing on a vacuum metalized surface augments the sophisticated appearance of the print.

※ Fine printing is not suitable for all substrate materials, although it can be used for workpieces with no vacuum metalized surface.

Ink-Jet Printing (On-Demand Printing)

Ink-jet printing is a type of on-demand printing. This printing technique uses a digital printer that prints out images directly from digital graphic data, without using a printing plate: the ink is atomized and sprayed directly onto a workpiece. Ink-jet printing is easy and can be used even for only one workpiece. The method can easily print photographs, and permits more advanced expression techniques such as overprinting of gradient colors.

※ Printed surfaces should be flat in principle.

※ Printed surfaces (ink) are not expected to be lustrous.

※ Consult us for workpieces that can be decorate by ink-jet printing.

Other On-Demand Printing Option

Transfer Foil / Shrink Film / Lamination Pouch

On-demand printing refers to a digital printing system that prints digital data directly onto a workpiece without using a plate as is conventionally required. This printing technique can be used with transfer foils, shrink films and lamination pouches. One type of on-demand printing system can even print vacuum metalized aluminum foil while simultaneously printing ordinary colors. These printing techniques are sometimes used to produce proofs for gravure printing.

※ The films (adhesive layers) that can be used with these printing options are limited compared with gravure printing.

Case Study

- 1. D-30 Oval(coloring, dry offset printing)+DW-T(Outer cap:natural color, internal paint )

- 2. CORONA-50(coloring, silk screen printing(organic))+CL-C(Inner cap:coloring /Outer cap:natural color, silk screen printing(organic))

- 3. PK-100L(frost, silk screen printing(ceramic))+SC-L(vacuum metalized )

- 4. KN-120L(frost, silk screen printing(UV thick build-up, UV))+KOQ-L(Inner cap:vacuum metalized /Outer cap:natural color)

- ※ UV thick build-up printing excluding the type areas (black)

- 1. RUPIA-80(Inner jar:coloring/Outer jar:coloring , silk screen printing )+RUPIA-80CAP(coloring , hot stamping(roller)

- 2. CLEA-40(Inner jar:coloring /Outer jar:natural color, transfer)+ CLO-C(coloring )

- 3. KN-100A(paint , silk screen printing , hot stamping(hot process))+Z-200-C023(coloring, hot stamping(roller, cutout))+PVC-430(natural color)

- 4. SAC DX-40(Inner jar:vacuum metalized/Outer jar:natural color, gradient paint , hot stamping)+SAC DX-40CAP(vacuum metalized)

- 1. Reference(gravure printing)

- 2. OKP-160(coloring, shrink )+OKP One-Touch(coloring )

- 3. IBR-150A(coloring, shrink )+Z-500-C009(coloring )

- 4. MFS-30(coloring, shrink )+DMF-CAP(Outer cap:natural color, internal paint, hot stamping )

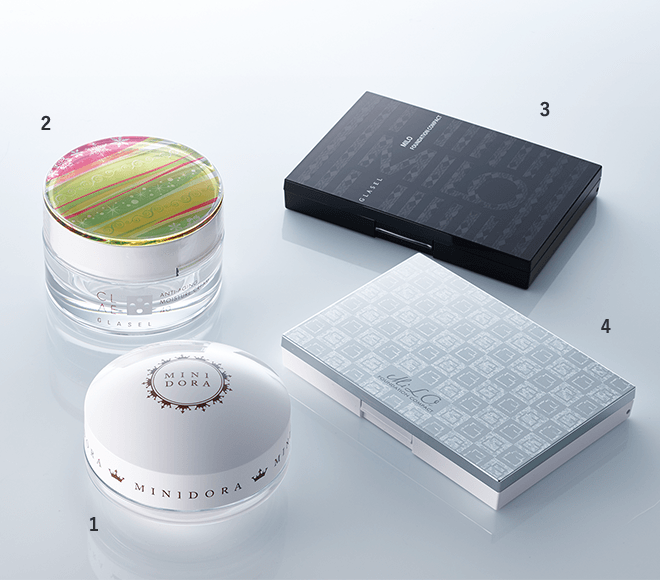

- 1. MINI DORA(Body:natural color/Cap:coloring , pad printing, silk screen printing)

- 2. CLEA-40(Inner jar : natural color/Outer jar : natural color, silk screen printing, hot stamping)+ CL-C (Inner cap : coloring/Outer cap: natural color, ink-jet printing)

- 3.MILO Compact (Body : coloring/Lid : vacuum metalized, fine printing, silk screen printing)

- 4. MILO Compact(Body:coloring/Lid:coloring, fine printing, silk screen printing)