PRODUCTS

Metal

Covering

for PLASTIC / GLASS

Metal coverings over caps and dispensers give accessories a luxurious appearance specific to metal.

Metal Covering

Metal coverings used on cosmetic containers are

mostly formed by drawing.

Aluminum is the most

widely-used metal for this purpose.

A piece of sheet aluminum is drawn (and compressed)

by pressure.

The drawn part is bonded to a container

with a hot-melt adhesive.

Metal covering on bottle

Engraving (projecting)

Engraving (indented)

Aluminum Anodizing

Aluminum anodizing is a coating process,

in which the surface of an aluminum workpiece is

used as

an anode and is oxidized

in a strong acid by electrolysis of water.

The purpose of aluminum anodizing is to improve the

corrosion

and wear resistance of aluminum

and to provide electrical insulation and decoration.

Example Variations of Anodized Aluminum

Glossy Anodized Aluminum

General natural anodized aluminum is colored silver and is shiny like a metal.

Semigloss Anodized Aluminum

Before anodizing, the roughened substrate surface is buffed* or chemically polished to achieve a gloss finish with depth.

* It is recommended to check an actual product by filling and conducting a test to verify its resistance to the contents.

Dyed Anodized Aluminum

A dye or other substance is applied to color the substrate. While the standard color is gold, other color variations are available including red and blue.

Double Anodizing

After masking any desired area, an anodized workpiece is subjected to a chemical to remove the rest of the oxide film and is anodized again.

Satin-Finished Anodized Aluminum

The substrate surface is roughened by a special chemical before it is anodized. The result is a matte finish.

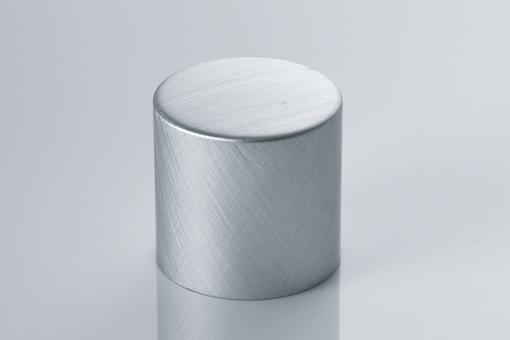

Brushed Finish

The substrate surface is brushed before being anodized.

Differences between

Metal Covering,

Vacuum Metalized

and Hot Stamping

Metallic surfaces are formed by metal covering, vacuum metalized and hot stamping.

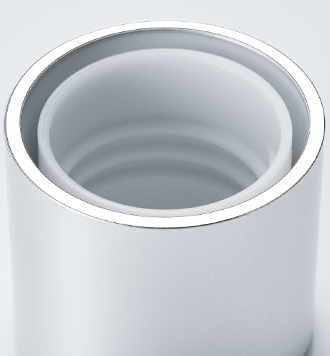

Metal Covering

A stamped metal part (aluminum) is fitted over a molded item. A back taper or other forms that are impossible to fit cannot be achieved by metal covering.

Metal covering reveals a boundary between the molded item and the metal part. The metal part feels cool to the touch.

Vacuum Metalized

A molded item is vacuum metalized with aluminum.

※ Three-dimensional curved surfaces can be “vacuum metalized”.

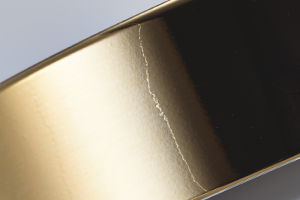

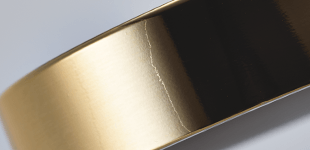

Hot Stamping

A foil is affixed to a molded item by pressure and heat.Hot stamping is suitable for two-dimensional curved surfaces, but not for three-dimensional curved surfaces.

A seam appears when hot stamping is applied on a side or other surfaces around which the foil is wrapped.

※ For details, see “Printing/Hot Stamping”

Case Study

- 1. Jam glass jar-120(clear, adhesive label )+S56CAP*(paint )

- * The S56CAP is not a plastic cap with a metal covering. It is a metal cap internally painted to prevent corrosion so that the cap can be used directly on a jar.

- 2. KN-30C(clear, silk screen printing )+KN-FC(metal covering)(semigloss anodized aluminum)

- 3. LF-30A(frost , silk screen printing , hot stamping )+CLF OVERCAP(metal covering)(dyed, satin-finished anodized aluminum)

- 4. IBR-100L(natural color, silk screen printing )+ST-PP(metal covering)(dyed anodized aluminum)

- 5. BL-80A(natural color, silk screen printing )+Z-200-C022(metal covering)(Inside:coloring /Outside:gloss anodized aluminum)+OVERCAP(natural color)