CSR・SDGs

Project 1

Raw Materials

CO₂ Emission-reducing

Additive Green Nano

Material

- Direct blow molding PET / PE /

Injection molding PET / PP / PE / ABS /

Extrusion PE / Compression PE

Assessment of CO₂ emissions

from incineration

Green Nano is a technology for reducing CO₂ emissions during incineration. It reduces CO₂ emissions during incineration when 3% is added to the conventional raw material. This technology, developed in Japan, is designed to reduce environmental impact. Green Nano products compare favorably with conventional products in dropping performance, workability, and appearance (in-house comparison).

※ The reduction rate of CO₂ varies with the composition and blended amounts of your product.

※ These products can be used in a similar manner to conventional products.

※ Please always check the items by making prototypes.

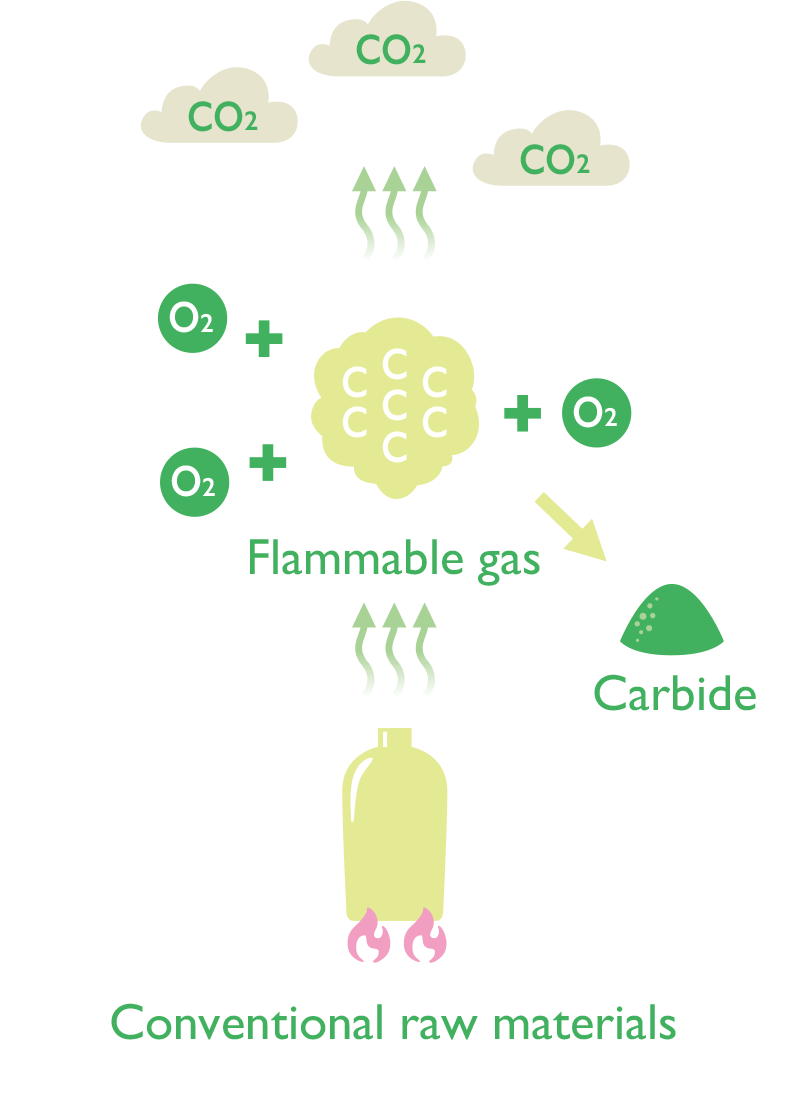

Mechanism of the CO₂

Emission-reducing Additive

General products

When heated, plastics generate a flammable gas.The carbon (C) contained in the gas bonds with oxygen (O₂) in the air to form carbon dioxide (CO₂).

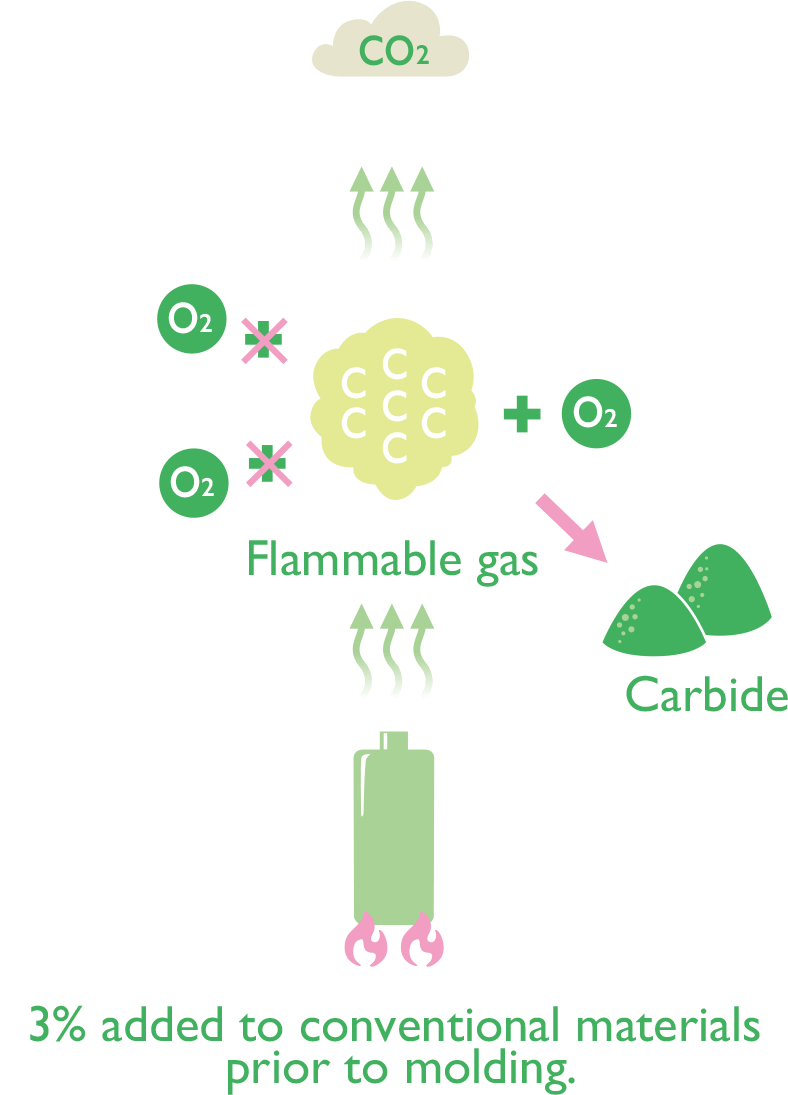

Green Nano products

The carbonization promoter in Green Nano CO₂ OFF fixes C in carbide before C bonds with O₂. As a result, CO₂. As a result, CO₂ production is reduced.

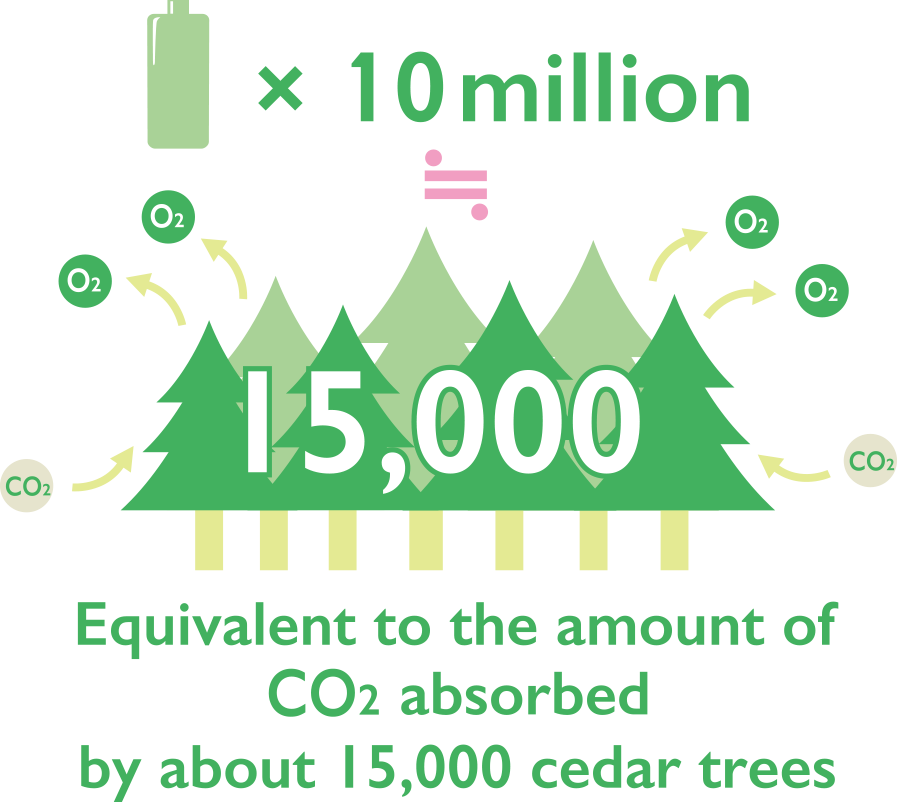

Simulated Reduction of CO₂ Emissions Produced from Incineration

Adding Green Nano to 10 million containers each weighing 16g,

assuming CO₂ emissions reduction of 60%.

CO₂ emissions from incineration of

A

B

Conventional plastics

Green Nano-added plastics

: 366,400kg

: 146,560kg

A-B = 219,840kg

Equivalent to the amount of CO₂ absorbed by 15,000 cedar trees in a year

Computational Assumptions

- ・CO₂ produced from complete combustion of 1g of PET: 2.29g(Calculation based on molecular

- ・Amount of CO₂ absorbed by one cedar tree in a year : 14kg

- ・Reduction in plastics-originated CO₂ emissions by Green Nano : 60%

- ・No. of cedar trees per hectare in a 50-year-old planted forest: approx. 900(Trial calculation based on the Forestry Agencyʼs website)

※ In the catalog, applicable products are indicated with a logo . Please contact us for more information.

. Please contact us for more information.

- Direct blow molding PET / PE

- Injection molding PET

- Injection molding PP / PE

- Injection molding ABS

Biomass Plastics

Material

- Direct blow molding PE /

Injection molding PE /

Extrusion PE / Compression PE /

Injection stretch blow molding PET /

Injection molding PET

Bio-PE

(Bio-polyethylene)

01

Bio-PET

(Bio-polyethylene terephthalate)

02

Material

Direct blow molding PE /

Injection molding PE / Extrusion PE /

Compression PE

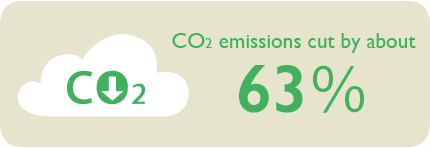

Biomass-derived 96%

Material

Injection stretch blow molding PET

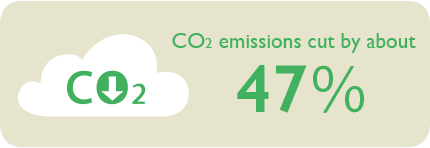

Biomass-derived 30%

Material

Injection molding PET

Biomass-derived 25%

※1 Assessment of CO₂ emissions from processes encompassing pellet production, transport to Japan, use as containers and disposal by incineration.

※2 This data evaluates CO₂ emissions from the procurement of raw materials to the production of pellets until their import to Japan.

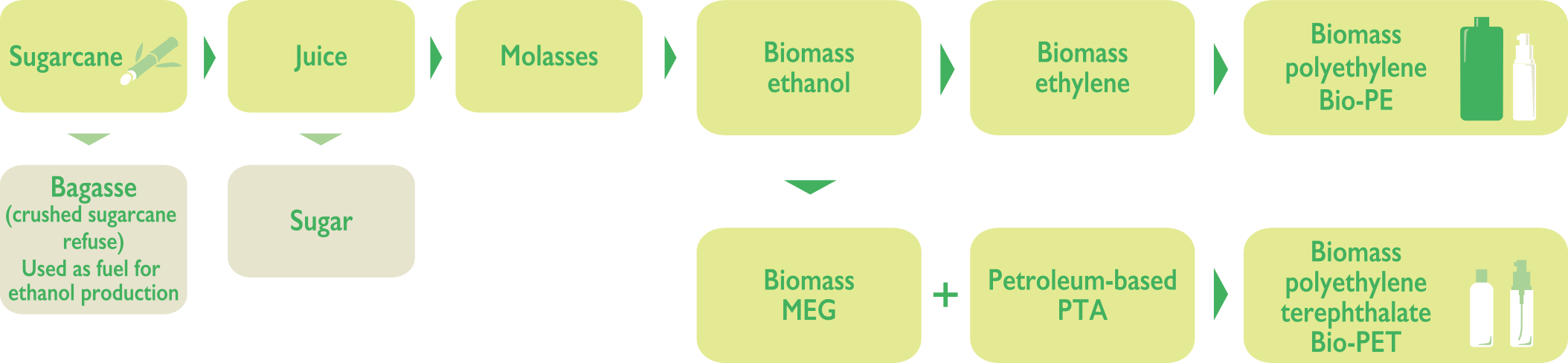

These are carbon-neutral* plant-based (biomass) plastics, which cause a lower environmental burden, as substitutes for conventional petroleum-based plastics. Bio-PE and Bio-PET can be used in a similar manner to conventional PE and PET. The source bioethanol is produced by fermenting molasses, which is the residue from refining sugarcane juice into sugar inmost cases. As it is produced from molasses, it does not affect or compete with food (sugar) production.

※ Can be molded using conventional molds and forming machines.

※ These items differ in grade from conventional products. Please

always check the items by making prototypes.

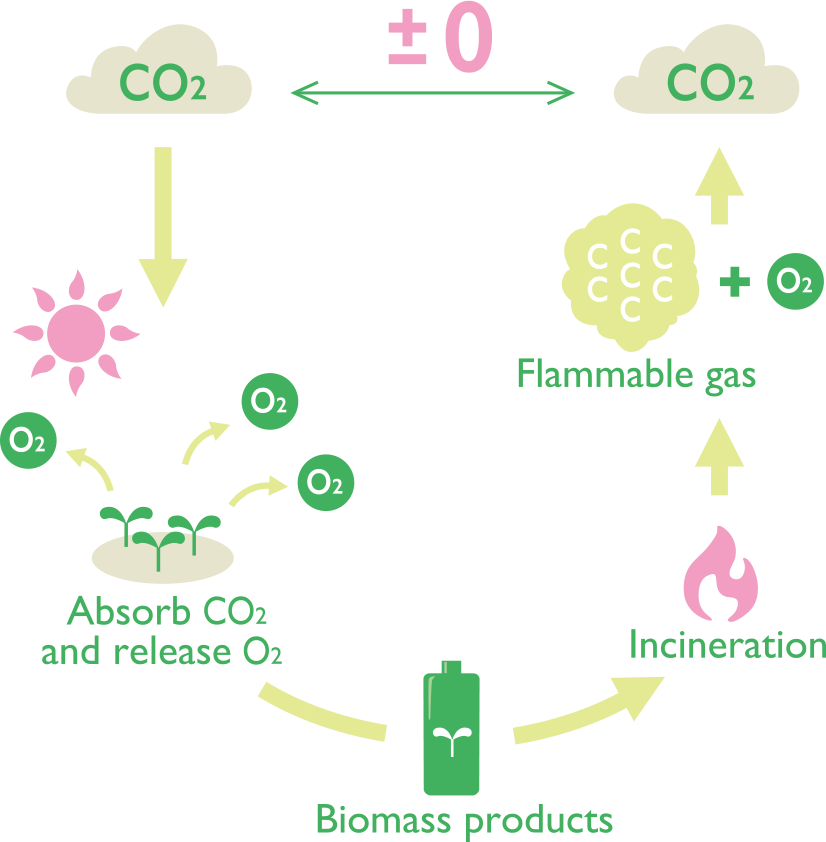

Carbon-neutral

Plastics made from plant material are environmentally friendly because they do not theoretically result in net CO₂ emissions even if they are incinerated on disposal, as the plants from which they are made absorb CO₂ as they grow.

Manufacturing Process

Plant-based PE and PET / Bio-PE, Bio-PET

Both bio-PE (direct blow-molded PE/injection-molded PE/extrusion PE/compression PE) and bio-PET (injection stretch blow-molded PET) raw materials have been certified and permitted to use the biomass plastics (BP) logo by the Japan BioPlastics Association (JBPA).To obtain the BP logo, the product must contain biomass plastics at least 25% by weight.

* Except for the injection stretch blow molding PET.

※ To use the BP logo, the issued registration number must also be shown.

※ In the catalog, applicable products are indicated with a logo . Please contact us for more information.

. Please contact us for more information.

- Bio-PE (Bio-polyethylene)

- Bio-PET

(Bio-polyethylene terephthalate)

Recycled Plastics

Material

- Iinjection stretch blow molding PET

Mechanically Recycled PET

※ Assessment of pellet production processes.

Collected used PET beverage bottles go through screening, crushing, and cleaning processes, followed by drying, and then are turned into PET flakes or pellets with their original functionality recovered.

※ Unlike conventional PET, which is colorless and transparent, recycled PET is transparent with a yellow tinge.

※ Recycled PET can be molded using conventional PET molding machines and molds.

※ These items differ in grade from conventional products. Please always check the items by making prototypes.

01

Chemically Recycled PET

※ Assessment of pellet production processes.

In addition to PET beverage bottles, all other used PET products are collected and used as raw materials, so there are abundant resources for chemically recycled PET. They are chemically decomposed (depolymerized) and recycled into raw PET materials.

02

※ In the catalog, applicable products are indicated with a logo . Please contact us for more information.

. Please contact us for more information.

※ We also handle recycled PP.

Paper

Material

- Injection molding PP

※ Assessment of CO₂ emissions from incineration.

This eco-friendly material contains 51% paper powder as the main ingredient. The material is categorized as a paper product and can be disposed of as flammable trash. When incinerated, it does not generate dioxins or any other toxic gases and cuts CO₂ emissions by about 28% compared with general plastic materials.

※ Comply with the rules set out by your local municipality.

※ These products require closer attention to factors such as chemical (water/oil) resistance than general plastic molded products.

※ These items differ in grade from conventional products. Please always check the items by making prototypes.

The material code for this material is “paper, PP. This raw material has been certified and permitted to use the Biomass logo by the Japan Organics Recycling Association (JORA).

※ For applicable products and further information, please contact us.

Glass

GLASEL uses at least 30% cullet* without plastic. Some products contain 100%* or 58〜60% cullet.

Cullet

Known also as recycled glass, cullet refers to scrap glass produced by crushing glass products (soda-lime glass) in their recycling process.

eco-friendly bottles

Bottle products that use at least 90% cullet as a raw material are known as “eco-friendly bottles.” They are as strong as common bottles, even if they are made with 100% cullet.

※ Cullet usage rates are indicated on each product page.

※ In the catalog, applicable products are indicated with a logo . Please contact us for more information.

. Please contact us for more information.

Limestone, Bamboo, Rice Husks, Discarded Rice, etc.

This PP contains limestone, bamboo, rice husks, discarded rice and other non-agricultural by products.

Additionally, GLASEL is exploring the use of newly emerging materials

as an alternative to fossil resources.